What Is Formwork? Types, Materials & Uses Explained

What is formwork?

Formwork is a temporary or permanent structure used in construction to shape, contain, and support wet concrete until it cures and becomes strong enough to support itself. It is a fundamental part of reinforced concrete construction, ensuring structural accuracy, safety, and the quality of the finished concrete surface.

Without properly designed and installed formwork, concrete elements such as slabs, beams, columns, and walls cannot achieve the required strength, alignment, or finish.

What Is Formwork in Construction?

In construction, formwork acts as a mould that holds freshly poured concrete in place while it sets. During this stage, concrete behaves like a liquid and exerts significant pressure on its surroundings. Formwork systems are designed to resist these loads, maintain precise dimensions, and prevent movement or failure during curing.

Formwork is used across nearly all concrete structures, from small domestic foundations to large-scale commercial buildings and infrastructure projects. Its design must account for:

Structural loads

Concrete pressure

Site conditions

Construction programme

Required surface finish

Well-planned formwork improves build quality, site safety, and overall project efficiency.

What Is Formwork Used For?

Formwork is used wherever concrete needs to be shaped or supported. Common applications include:

Foundations and ground beams

Ground-bearing and suspended slabs

Columns and vertical elements

Beams and transfer structures

Shear walls and retaining walls

Reinforced concrete frames

Infrastructure such as bridges and culverts

Each application places different demands on the formwork system, which is why material selection and installation method are critical. HYB Construction are formwork specialists, ensuring every pour meets both architectural and engineering requirements.

Types of Formwork

Different types of formwork are used depending on the structure, scale, and complexity of the project.

-

Timber formwork is one of the most traditional and widely used systems. It is easy to work with, adaptable to complex shapes, and cost-effective for small or bespoke projects. However, it has a limited lifespan, requires skilled labour, and is generally unsuitable for repetitive use on large projects.

-

Steel formwork is strong, durable, and capable of withstanding high concrete pressures. It provides an excellent surface finish and is ideal for repetitive construction, such as large commercial developments or infrastructure works. Although the upfront cost is higher, its long service life makes it economical for large-scale use.

-

Aluminium formwork offers similar benefits to steel but is significantly lighter, allowing faster handling and installation. It is commonly used in residential developments and high-volume housing projects where speed, consistency, and precision are essential.

-

Plastic formwork systems are lightweight, reusable, and resistant to moisture. They are often used for modular or repetitive designs and can be particularly effective for smaller structural elements and housing applications.

-

ICF is a permanent formwork system that remains in place after the concrete has cured. In addition to shaping the concrete, it provides insulation and improved thermal performance, making it popular in modern, energy-efficient construction.

Common Formwork Materials Explained

Formwork systems are typically manufactured from the following materials:

Timber and plywood – flexible, easy to modify, but limited reuse

Steel – high strength, long lifespan, excellent finish

Aluminium – lightweight, fast to install, precise

Plastic composites – reusable, weather-resistant, modular

The right material depends on project scale, budget, programme, and finish requirements.

Formwork Materials Comparison Table

This comparison highlights why professional selection and planning of formwork systems is essential for cost control and programme efficiency.

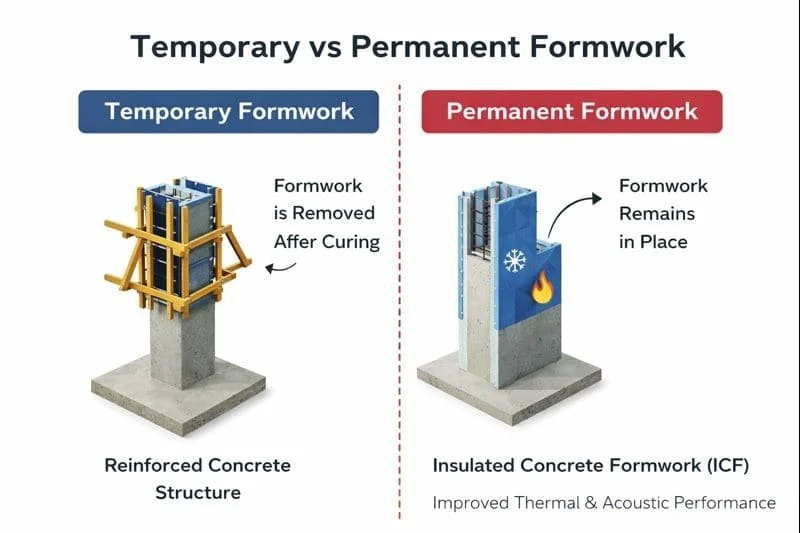

Temporary vs Permanent Formwork

Temporary formwork is removed once the concrete has gained sufficient strength. This is the most common approach and allows materials to be reused across multiple pours.

Permanent formwork, such as ICF, remains part of the finished structure. It reduces labour requirements and can improve thermal or acoustic performance, but requires careful upfront planning.

Choosing between the two depends on structural requirements, build programme, and long-term performance goals.

Formwork vs Shuttering vs Falsework (UK Context)

In the UK construction industry, these terms are often used interchangeably, but they have distinct meanings:

-

refers to the mould that shapes the concrete.

-

is commonly used to describe vertical formwork, such as walls and columns.

-

is the temporary support structure that holds the formwork in position and carries loads until the concrete cures.

Understanding the difference is important for safe design, installation, and compliance on site.

Why Professional Formwork Matters

Formwork is not just a temporary structure - it directly affects the safety, quality, and success of a concrete build. Professionally designed and installed formwork ensures:

Accurate dimensions and alignment

Safe management of concrete loads

Faster construction programmes

Reduced material waste and rework

High-quality concrete finishes

Compliance with site safety requirements

For complex or load-bearing structures, expert formwork planning is essential.

Learn more about our Formwork Services and how we support reinforced concrete projects from foundations to full structural frames.

FAQs About Formwork

-

Formwork is typically removed once the concrete has reached sufficient strength, which can range from 24 hours to several days depending on conditions and structural requirements.

-

Yes. Steel, aluminium, and plastic formwork systems are designed for multiple reuses, making them cost-effective on larger projects.

-

Formwork failure can lead to structural defects, safety risks, and costly delays. This is why correct design, installation, and inspection are critical.

-

Absolutely. The material and condition of the formwork directly influence the surface finish and accuracy of the concrete.

Conclusion

Understanding what formwork is - and choosing the right system - is essential for any concrete construction project. From foundations and slabs to reinforced concrete frames, well-designed formwork ensures structural integrity, safety, and efficiency throughout the build process.

Whether for small-scale works or large commercial developments, professional formwork plays a vital role in delivering successful concrete structures. If you’re planning a concrete project and want to ensure accuracy, safety, and efficiency on site, explore our Formwork Services to see how we support reinforced concrete structures from foundations to full structural frames. You may also find it useful to read our guide on RC Frame Construction to understand how formwork integrates into the wider structural build process.